Socket Head Cap Screw is a type of threaded fastener with a socket drive and a cylindrical head. They require a special wrench, usually hex, to install.

Hex socket button head caps screws have a large, flat load-bearing surface and are popular for their aesthetic and strength characteristics. They also enable greater clamping force in applications with limited clearance.

Materials

Socket Head Cap Screws have a hexagonal drive hole that accepts hex keys or wrenches, and are stronger than most other types of screws. They are commonly used in construction projects and often help crews complete jobs more quickly as fewer screws are needed to fasten assemblies. They also provide a safer alternative to using nut and bolts where space is limited.

They can be found in a variety of materials, including alloy steel and brass. They are available in both fully and partially threaded styles, depending on the application. Fully threaded fasteners have a tapped, threaded hole from the base of the head all the way to the top, while partially threaded versions leave an unthreaded portion under the head for more strength.

ISO 9001:2008 certified custom manufacturer of shoulder, socket head, square, Phillips & flat head cap & set screws. Also offers hex, truss & Allen head screws as well as knurled thumb, hex key adjusting & quarter turn screws. Finishes include passivate, thermal black oxide & zinc bake CR+3 and metric-sized options are also offered. Custom machining, prototyping & kitting services provided. Serves aerospace, automotive, aviation, chemical, energy, construction, medical & marine industries.

Threads

Standard socket head cap screws feature unified external threads that extend from one end of the screw to the other, with a chamfered leading edge and a hex recess that accepts a wrench. This hex structure allows the screw to be driven with an impact tool or a hex key (Allen key).

The head of these fasteners is recessed within the counterbore of the hole into which it fits, providing a flush and tidy appearance. They also provide significant tensile strength and clamping strength.

Some varieties of this specialty screw feature a nylon patch on their threads, which resist loosening caused by vibration. Other features include vented heads that allow air or fluid to pass through, preventing pressure imbalances; and nitronic steel, which combines the durability of alloy steel with corrosion resistance. Various standards exist to ensure consistency and safety, allowing manufacturers and users to adapt the threads and other characteristics of these screws to a variety of industry requirements.

Finishes

Socket head cap screws are also known as Allen screws or socket bolts, and feature a cylindrical headed fastener with an indented hex socket drive. They can be fully or partially threaded and are often found in machine tools, die fixturing and clamping applications. The head on these screws is generally smaller than other screw types and requires less space for installation.

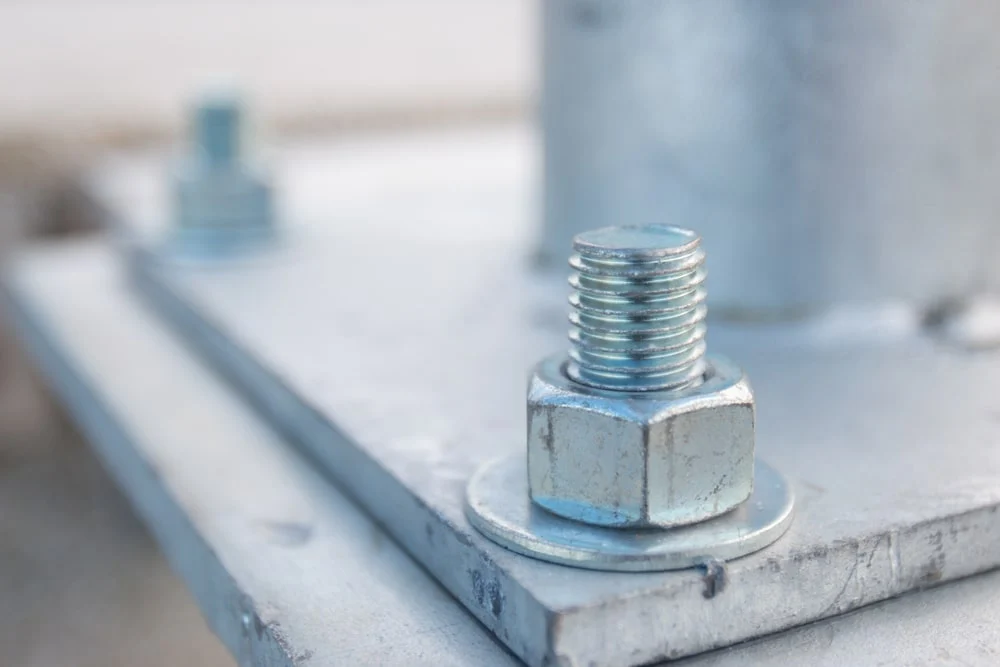

These fasteners are available in a variety of finishes, including black oxide and zinc plating. These finishes protect against corrosion and provide a sleek, black appearance. Washers are not typically required with these fasteners, but they can be used when extra strength is needed or when working with soft materials.

Our socket head cap screws are manufactured from grade 8 alloy steel, which provides great strength and corrosion resistance. These fasteners are ideal for use in a wide range of industries and applications like metal stamping dies, plastic injection molds, power transmission, hand and machine tools, and furniture.

Applications

Socket head cap screws are commonly used in industrial production and assembly applications due to their high clamping strength, ease of tightening and loosening, and sleek appearance. They can be found in many industries, including automotive, metal fabrication, furniture manufacturing, and steel construction.

These fasteners can be fully threaded or partially threaded, and they come in different lengths. Full-threaded screws can be installed and tightened all the way into threaded holes, while partially threaded screws leave an unthreaded shank portion between the screw head and the hex drive.

Some types of socket head cap screws feature special head designs, such as cup, cone, and flat head varieties that provide a better grip on parts without damaging them during tightening and removal. Others can be lubricated to reduce friction and prevent damage from vibrations. It is important to properly install and inspect these fasteners regularly for signs of wear, corrosion, or looseness. Regular inspection and proper maintenance can prevent costly downtime caused by equipment malfunction.